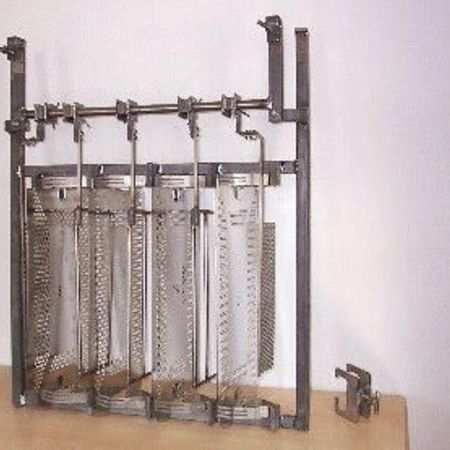

Titan rack construction

Current-carrying rack components and contacts are produced of pure titan

Application

- Preferably for small components in large-scale production

- The rack dimensioning is designed according to the power demand

- With patented special contacts also for widespread components

- For most anodizing processes suitable, except with fluoride-containing electrolytes and electrolytic dyeing

- for high currents TiCu-contacts with special structured surfaces can be inserted

Characteristic

- No stripping after every run

- High density of equipping possible

- High diversity of contacting options

- Good handling

- Short charging time

- Less carry-over of electrolyte

- Longer durability (as a rule extending over several years by right construction)

- Good possibilities for repair work

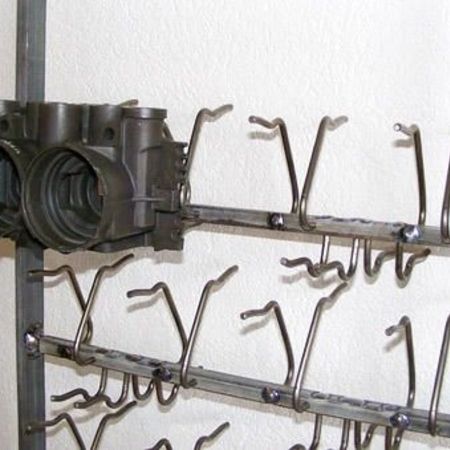

Special racks

In addition to established rack forms we are specialised to produce special racks for particularly demanding parts. We develop, prove and manufact prototypes to large-scale production according to your request.

The pictures below show special titanium racks with auxiliary cathodes and a special contacting option with changeover contact applications.